Driving Manufacturing Excellence with a Digital Thread

Join this 75-minute virtual and interactive launch event presenting PolyWorks® 2025. Gain valuable insights into the new features as our experts guide you through enhancements designed to boost your workflow and productivity.Learn how to establish a single source of truth and deliver data digitally to all stakeholders within a manufacturing organization by deploying a digital thread for 3D measurements.

Driving Manufacturing Excellence with a Digital Thread

Join this 75-minute virtual and interactive launch event presenting PolyWorks® 2025. Gain valuable insights into the new features as our experts guide you through enhancements designed to boost your workflow and productivity. Learn how to establish a single source of truth and deliver data digitally to all stakeholders within a manufacturing organization by deploying a digital thread for 3D measurements.

Driving Manufacturing Excellence with a Digital Thread

Join this 75-minute virtual and interactive launch event presenting PolyWorks® 2025. Gain valuable insights into the new features as our experts guide you through enhancements designed to boost your workflow and productivity. Learn how to establish a single source of truth and deliver data digitally to all stakeholders within a manufacturing organization by deploying a digital thread for 3D measurements.

See how improve your inspection workflows with repeatable measurement processes and 3D data capture optimized for accuracy and speed by combining PolyWorks|Inspector™ and the FARO® Quantum Max ScanArm.

Discover how to perform multipiece feature-based inspections without a usable CAD representation more efficiently, with probing guidance plus feature scanning guidance and automatic feature extraction, thanks to the measurement guides technology introduced in PolyWorks|Inspector™ 2022.

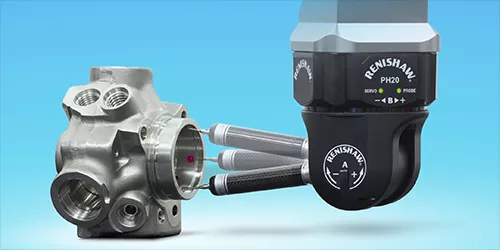

Transform collision-free 3-axis CNC CMM sequences into optimal 5-axis sequences by efficiently integrating 5-axis moves and head touch probing.

See how measurement operators can execute probing workflows more efficiently by displaying guidance arrows, measurement instructions, probed points, and common probing functionalities before their eyes using the Microsoft HoloLens smart glasses and PolyWorks|AR™ 2022.

Discover how manufacturing companies can gradually deploy the PolyWorks 3D metrology digital ecosystem to avoid disturbing operations and obtain efficiency gains at every step of their digital transformation journey.

Discover how to efficiently perform a multipiece dimensional analysis on complex geometries using PolyWorks|Inspector™ controlling powerful Hexagon SLS scanners and turntables.

Discover how manufacturing companies can perform root cause analyses of urgent dimensional control issues significantly faster by accessing 3D metrology data and results in real time with PolyWorks|DataLoop™.

Learn how PolyWorks|AR™, a PolyWorks|Inspector™ mixed reality plug-in for the Microsoft HoloLens smart glasses, radically transforms the experience of measurement operators by superimposing vivid holograms on physical pieces and assemblies.

To obtain trustworthy results, a measurement system analysis (MSA) is performed prior to production through repeatability and Gauge R&R studies. InnovMetric proposes an easy-to-use and fully integrated software solution to perform these studies.

See how we made the transformation and understand how the PolyWorks enterprise solution can directly contribute to enhancing your company’s competitivity and increasing the value of your expertise.