Optimizing 3D Measurement Processes at Framatome with PolyWorks|Inspector™

At the Jeumont production site, 3D measurement efficiency is enhanced through the versatility of PolyWorks|Inspector

Since 1970, the Framatome Jeumont site has specialized in designing, manufacturing, and maintaining critical components for nuclear power plants.

The main components produced include the Primary Moto-Pump Groups (GMPPs), which ensure the circulation of the primary fluid in the reactor, and the Control Mechanisms for Fuel Assemblies (MCGs), which regulate reactor power. These components are crucial for nuclear reactor safety.

The Challenge

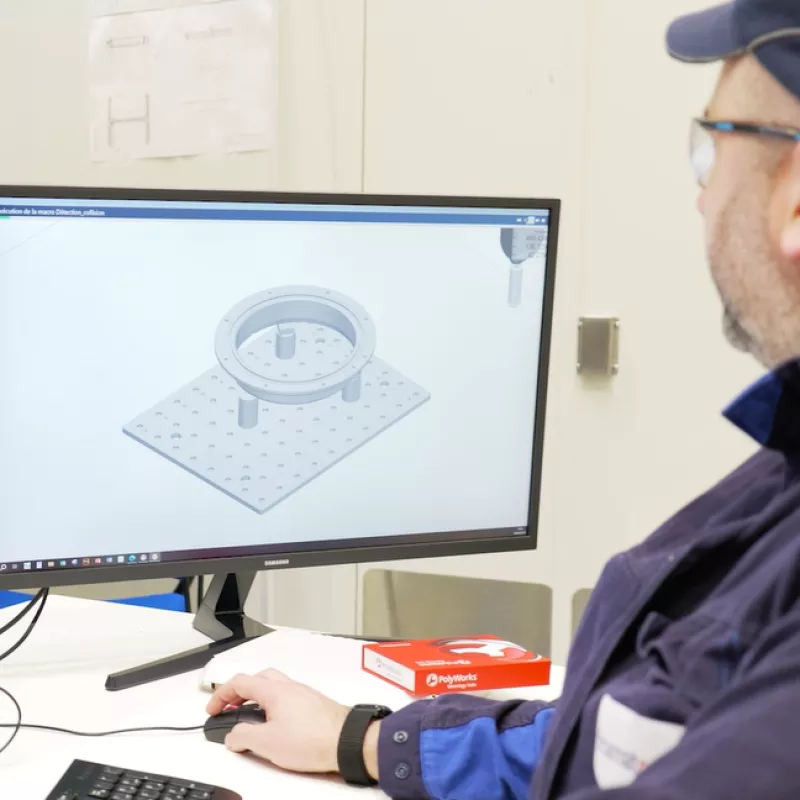

Metrologists use a variety of tools including articulated arms, 3D scanners, and CMMs from brands like Leitz, Zeiss, and Mitutoyo. To enhance operator flexibility and significantly reduce inspection times, Framatome decided to consolidate its measurement tools under a single software.

PolyWorks|Inspector was chosen for its compatibility with all types of 3D measurement equipment, ease of programming, and the ability to instantly transfer programs between machines.

“We were amazed by the software’s versatility. For me and my colleagues, it was clear that this was the solution we had been looking for.”

Pascal Huriaux, Methods and Control Technician, Framatome Jeumont.

The Solution

Introduced several years ago, PolyWorks|Inspector has centralized operations onto a single platform, reducing production times and costs.

Initially used with portable equipment like Hexagon arms, PolyWorks|Inspector was later extended to CMMs. Its user-friendliness won over the metrology department. More recently, a demonstration of digital manual measuring instruments highlighted its versatility even further.

The team chose to standardize their practices and expand their licenses.

Framatome is also exploring the integration of PolyWorks|DataLoop™ as part of its digital transformation. This solution could provide rapid access to measurement programs through a search engine and offer greater flexibility in managing and sharing 3D measurement data within teams.