Driving Safety and Saving Lives:

Humanetics Makes Good Use of PolyWorks®

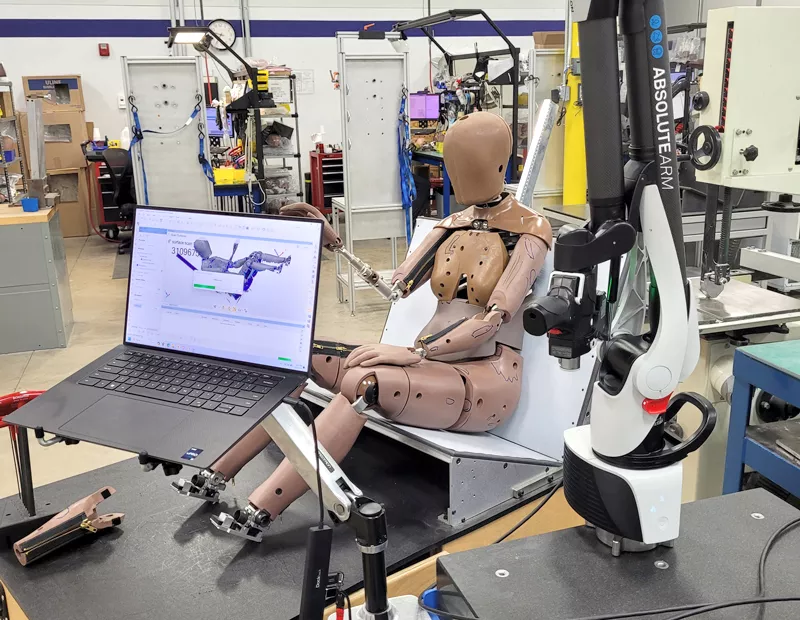

As the world leader in crash test dummies, new designs with more high-tech features are appearing daily. PolyWorks|Inspector™ helps Humanetics share information and stay ahead of the curve.

Humanetics is the world’s largest manufacturer of anthropomorphic test devices (ATDs), commonly known as crash test dummies. The group has more than 1000 employees across 26 facilities located around the world with its global corporate headquarters in Farmington Hills, Michigan, USA.

Humanetics is experiencing tremendous organic growth as its technology-driven safety solutions are increasingly in demand by the automotive, aerospace, military, consumer products industries, and many others.

The Challenges

The Humanetics quality department was facing several challenges. “Compared to 50 years ago, we are seeing more and more technology driven into the latest generations of ATDs,” says Chad Myerick, Senior Global Quality Manager. “In terms of sensors and bio-fidelity, tolerancing and finding space for such features is vitally important.”

Additionally, with significant company expansion underway, the company required an innovative metrology solution that was user-friendly and easy to learn and operate to not only expand the capabilities of the quality inspection team but to quickly get up to speed on new and existing metrology equipment.

Humanetics manufactures crash test dummies in its Huron, Ohio plant, but designs and manufactures a growing variety of test sensors in Farmington Hills, Michigan.

“We needed to standardize across both facilities and have the ability to transfer data, transfer knowledge, across both facilities with consistent programming across metrology equipment in both locations,” Myerick points out.

Chad Myerick, Senior Global Quality Manager at Humanetics.

Casey Unger, Quality Supervisor at Humanetics.

In addition, quality requirements were growing. “We do everything here from engineering mold components to five-axis CNC machining of extremely complex parts,” says Casey Unger, Quality Supervisor.

“We see new designs and prototypes every day. Tolerances are only getting tighter. We have to provide more precise parts and have a system in place to provide that precision to our customers.”

Also, the CMM programming was very time-consuming and difficult using its native software, and had to be completed by a highly trained and knowledgeable individual. Quality needed a more user-friendly solution that would open up this task to more people and shorten cycle time with no sacrifice in accuracy and completeness. Reporting was also a challenge. “We used to hand-write dimensions on prints, and old CMM reports were hard to read,” Unger describes.

Finally, expansion also means expanding duties and responsibilities for existing quality department personnel and the need for new programmers. Additional support and training, together with ease of use, were essential to succeed.

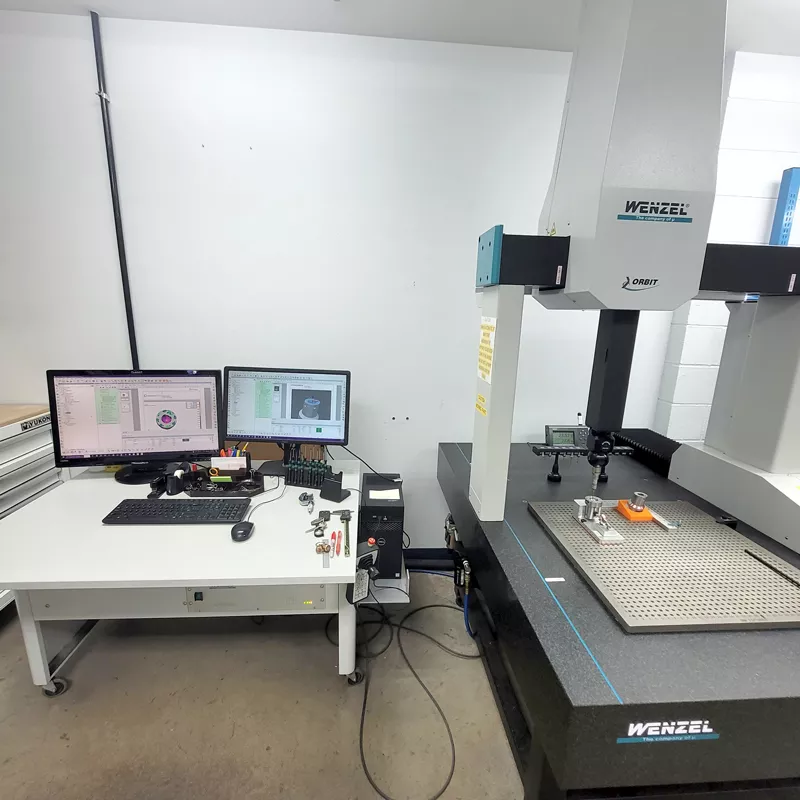

Humanetics' Quality Control team use PolyWorks|Inspector with a Wenzel XO55 CMM to measure parts.

The Solutions

“We have been using PolyWorks|Inspector and PolyWorks|Reviewer™ in our quality-control process for many years with various metrology equipment,” says Unger.

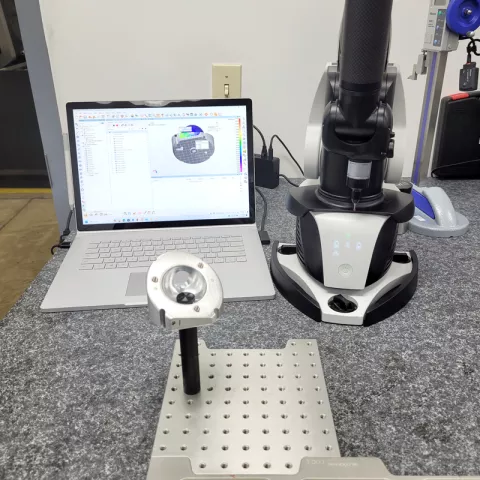

He decided to try programming the CMM using one of the CMM plug-ins included in PolyWorks|Inspector. Although Unger had previous PolyWorks® experience taking dimensions with a portable arm, “I had no programming knowledge on a CMM,” he says. “I did some investigating on YouTube, watched the training videos, and sat down and started programming on the CMM. It was that easy for me and much easier than what we were typically doing at the time.”

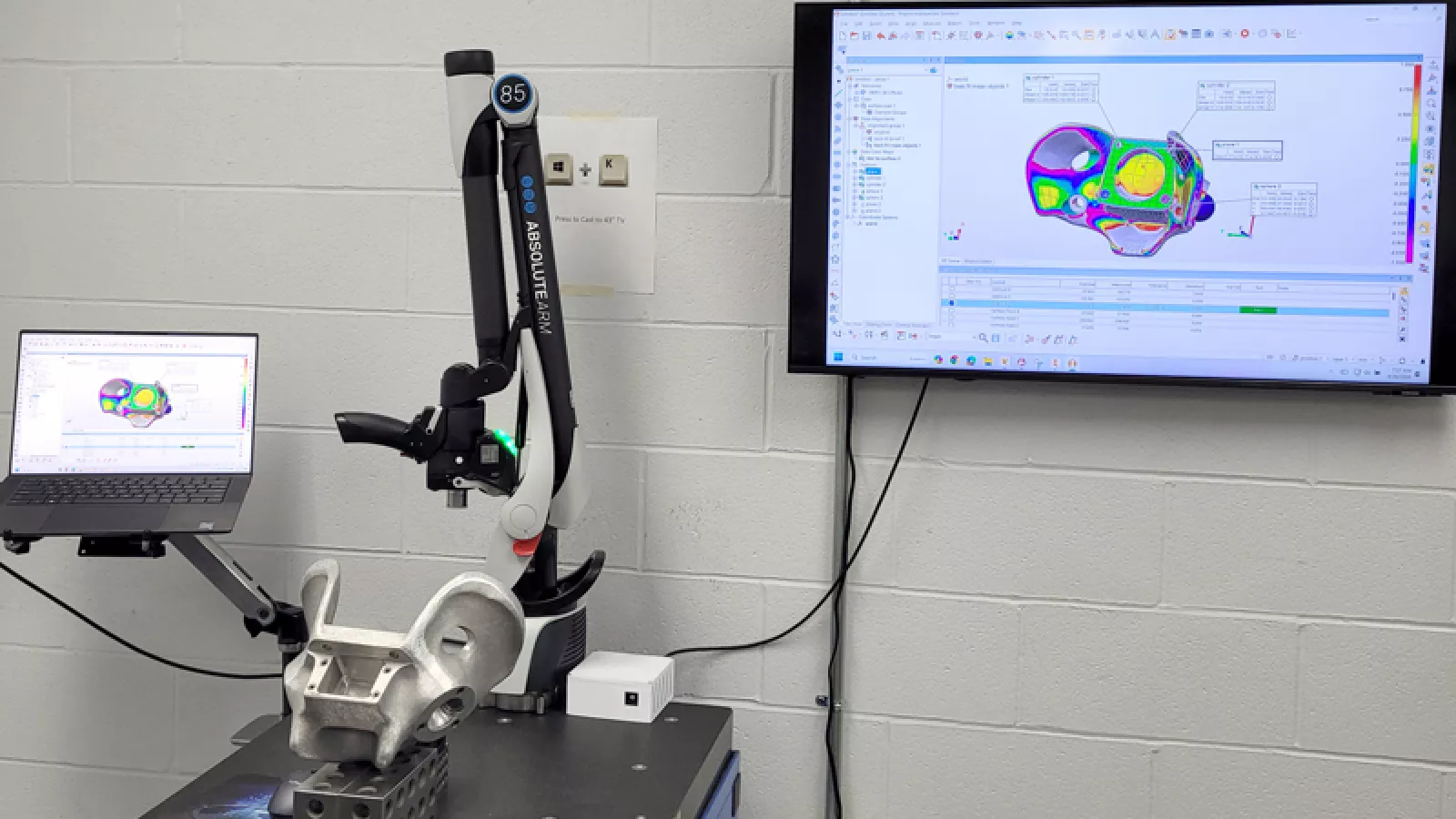

How about those old CMM reports? In PolyWorks|Inspector, inspection reports with graphical data, tables, and color maps can be created easily, greatly enhancing report quality and efficiency.

And when Quality needed help, the excellent PolyWorks technical support helped them solve their problems and keep moving forward.

PolyWorks|Inspector is the ideal tool as it connects to major-brand CNC CMMs, portable probing devices, and point-cloud scanning devices, allowing Humanetics to consistently and quickly get metrology results out to various engineering departments, machine shop supervisors, and others.

Both facilities can now utilize the same planning, inspection, and reporting process across a common metrology workflow.

The Benefits

Universal Platform

Capital equipment decisions at Humanetics, particularly in a period of high growth, are now driven by ‘Does it integrate with our software?’ Unger added. PolyWorks|Inspector runs on Humanetics’ portable arms, CMM, and 3D scanning equipment, making sharing precise data from multiple sources more efficient.

Ease of Use

Humanetics reported that, on average, CMM programming time with PolyWorks|Inspector is 76% faster than previously, and its ease of use helps get new employees up to speed.

Scanning a pelvis bone using a Hexagon AS1 3D scanner and PolyWorks|Inspector.

Humanetics had lost the CMM programmer at their Michigan location but was able to hire someone with prior PolyWorks experience on a portable device, like Unger. Since the new person had some foundational PolyWorks experience, Humanetics was able to graduate her to the CMM with confidence in continued success due to the ease of use of the software and the excellent technical support.

As a result, Humanetics can be more flexible and agile in the face of inevitable staff changes.

The PolyWorks universal 3D metrology software allows Humanetics to use the same software on different measuring equipment.

Better Reporting

The resulting standardization of reports from all metrology equipment has improved the ability to interpret results, which helps with manufacturing changes on critical parts. “We can also easily share data and cascade better design decisions. A lot of advanced technology is continually being engineered into these components and we need intuitive metrology software to keep up,” Unger explains.

“We’ve gotten our bearings with PolyWorks|Inspector and look forward to incorporating more features like 3D scanning and reverse engineering,” Myerick says.

“From our 1950s dummies to the latest generations, we have to be able to encompass and communicate all part dimensional knowledge in a timely manner. PolyWorks|Inspector helps keep us ahead of the curve,” concludes Chad Myerick.

Learn more about Humanetics

PolyWorks|Reviewer™

PolyWorks|Reviewer™