From subcontractor to partner, including third-party jobs

When product price is no longer the main criterion to pass an order

OSIM (S.r.l.), a mechanical subcontracting company from Modena, Italy, went from offering quality products in an increasingly competitive market to becoming irreplaceable for their clients by making metrological investments.

The Challenge

OSIM is based in San Prospero (MO) and does mechanical processing for third parties. Like many typical Italian small- and medium-sized enterprises (SMEs) working as mechanical subcontractors (welding, deep drawing, cutting, folding, puncturing, laser cutting, etc.), OSIM was facing competition from companies based in emerging economies. They decided they needed to develop evolved competencies and innovative technologies in order to be able to offer clients not just compliant, certified products of high quality and reliability, but also services that could allow them to stand as real partners with solid know-how to offer customers, without this having to weigh on costs.

The Solution

The plant manager explains the company strategy for evolution in more detail. “We decided to increase the level of our offer by adding features that are a lot more evolved with respect to the low product price. And we did this by investing substantially in innovative methods and technologies, as well as in personnel training, because people are the main resource that any company can and must have. It was not an instant transformation, but it was a radical one, as we gradually went from being a simple provider to being a partner able not only to make the piece but also to improve it and make it more competitive even in the project and trial/quality control phases, which was a fundamental asset to the client as far as co-design is concerned. So, we started providing clients with competencies they often lack internally, in spite of their size, which is always so much greater than ours. In addition, we began directly carrying out a whole series of product controls that customers demand in an increasingly informed way but that are decreasingly recognized as far as costs.”

Alex Nakhleh, OSIM's Trial Inspector.

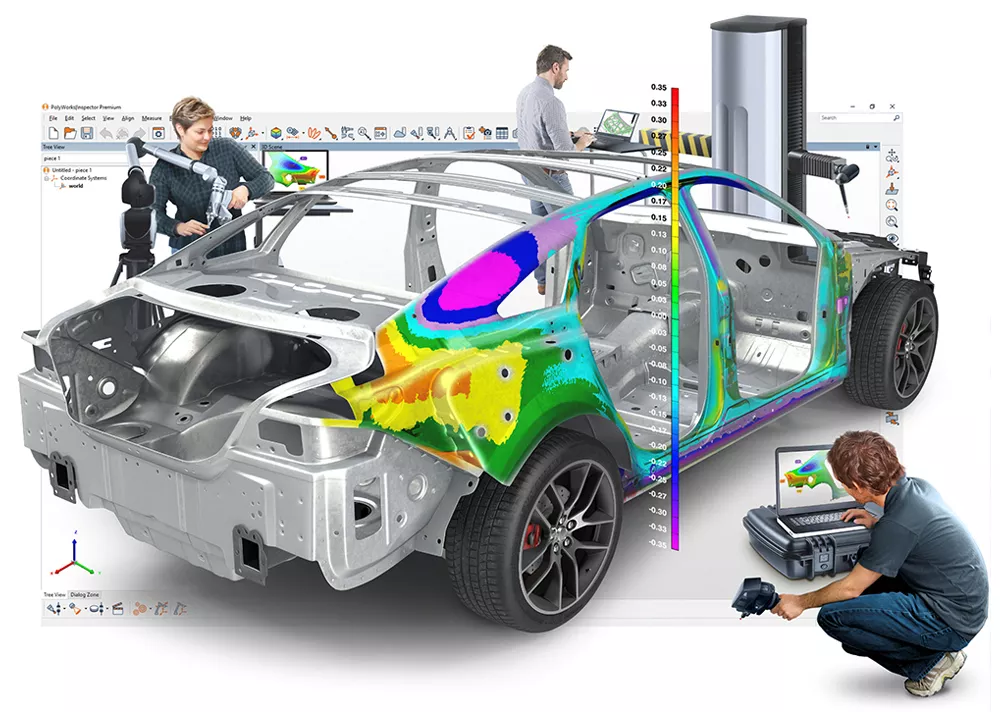

The decision to guarantee the quality of products and processes meant investing in their metrology equipment. Explains Alex Nakhleh, Trial Inspector, “We decided to expand and completely renew our essential metrology room, and this was done from a perspective of full awareness on the part of our directives of the need to satisfy growing customer demands regarding product guarantees. During that period, we purchased an arm-based device, which we needed to scan and then check the alignment of reference targets relative to certain coordinates. These checks were related to a cabin for which we were producing just one part, so we couldn’t really know where the origin of these targets was.

The arm-based device provider helped us solve this by advising us to add measuring software that was more evolved than the one that came with the arm, called PolyWorks|Inspector™. It is produced by InnovMetric, a Canadian company with a subsidiary in Italy, PolyWorks Europa Italia. With this new 3D inspection software, we immediately accumulated inestimable savings, as we were able to detect the targets and align the piece in just one minute, thus ensuring the highest possible precision of the operation. For a novice trial inspector like myself, it was like coming to the Valley of Eden. Besides, I had the support of a training course and an over-the-phone help service staffed with very experienced application specialists who were able to indicate, in just a few minutes, the best solution to my technical questions so I could get right back to work.”

The plant manager adds, “Post-sales support is already a must for us when it comes to choosing providers of new technologies of any kind. In the case of the PolyWorks® software, we must highlight not only the quality and efficiency of the support services offered but also their ability to really listen to client observations and suggestions, because that then as product improvements that are made available to clients through regular software updates.”

Apart from the traditional instruments (micrometers, dial indicators, dial gauges, calipers, etc.), OSIM also has a CMM, a profile projector, a roughness tester, the measuring/scanning arm we mentioned before, and other instruments to carry out destructive and nondestructive testing. Their metallographic lab is equipped with hardness testers, measuring microscopes, a manual buffing and polishing press, and a Liquid Penetrant Testing (PT) system, a form of non-destructive testing. Plus, they can provide samples and prototypes, including the manufacturing of provisional equipment destined for production testing.

Investing in employee development was also a key element. Says Nakhleh, 32, “I am still in a phase of full professional growth, and thanks to PolyWorks Europa Italia I’ve learned to understand objects, in PolyWorks|Inspector, how to create them, and how to make them efficient with the right methods of alignment, all of which has taken me on an evolved training trajectory, mainly on the job. OSIM’s growth in the areas of welding and pressing has really helped me to understand metallurgy at a deeper level. Gradually, I’ve learned to visualize the behavior of materials in a more flexible way, as is the case, for example, with deep metal sheet drawing. And that training, which my company has given me throughout the years, I am now able to give back as know-how, competence, and client service. My personal experience can serve as a testimony for young people, even today, of how it is possible to find important spaces to grow professionally, as a person, and to express one’s own – often unexpressed – potential. But to make it you need curiosity, will, hard work, and of course the trust of a bold company like OSIM who wants and knows how to optimize our competencies!”

The Benefits

For OSIM, investing in metrology produced a lot of added value and greatly contributed to enhancing the level of their offer so they can eventually become an actual partner for their client companies and thus acquire that irreplaceable status. Says the plant manager, “The technological and human resources we have allow Alex to act, when needed, as a quality control manager, a position that doesn’t even exist at the client company despite their being much larger than us. It is a position that would be costly and difficult for them to assume, train, and equip with all the best technology so they could carry out all the necessary checks internally.”

“So, a small company like ours has chosen to adapt its structure according to needs in order to be able to carry out high-level diagnostics of particular aspects for its clients, supporting them also during project phases, obviously without expecting to be paid for such services. In turn, we obtain a much larger benefit which is to be recognized as a trusted partner that deserves to be rewarded with substantial jobs that represent both quantitative and qualitative growth. And these rewards also come from the market, as our presence is continually being promoted before other potential clients. In short, by mustering the courage to invest reasonably in oneself it is possible, for any SME, to acquire more value in the context of a market that has just figured out how to keep prices down.”

Nakhlek continues, “At the job acquisition stage, the added value we can offer clients becomes relevant when we determine what we need to produce the new part, or what checks will be necessary, and if we’re able to provide them. In the case of a stirrup, a seemingly simple piece, after scanning the first ones we found a way to accelerate the successive control operations and make them efficient with respect to the end client’s assembly criteria, all of which helped us build the control jigs. In short, by just conducting a scan and a few checks we learned to produce a real best-fit for the piece itself that was efficient and fast. All of this creates a synergy with the production process and certainly represents an important competitive advantage in terms of our offer as a company..”

The current market understands OSIM’s evolution and has rewarded it financially. “Yes, definitely,” confirms the plant manager, “if we are to judge from our financial results and from the constant increase in potential new clients. They come looking for high-quality providers, so, when they contact us, they already know that our pieces will by no means be dirt cheap, but that our prices will be fair in relation to the quality of the products and services we offer. Since the high level of our production is a given, our service and the guarantees we can offer on products are precisely what potential clients come looking for.”

“OSIM will continue investing in the metrology sector,” explains the plant manager, “because clients are always asking for new services that guarantee quality, and we also like to propose new types of controls. The path we chose is already clear and defined: We aim to produce every piece according to precise characteristics, with zero waste, and to do this we have to equip our company with the necessary instruments to be able to verify this with maximum precision, at the right moment. In order to keep improving our quality, it is fundamental that we own increasingly evolved metrological instruments that can satisfy very specific demands, which are always growing.”

The efforts and investments carried out in the last years by OSIM, which have already become a constant, produced results that were far better than expected despite the pandemic period, which is not yet over: their sales volume went from 3.7 million Euros in 2019 to about 6 million Euros foreseen by the end of 2021. But this exponential growth could also be observed, at least in part, in the substantial balance obtained by the end of 2020 compared to 2019, even after a few weeks of inactivity imposed by the various lockdowns. This growth also affected their number of employees (which has gone up to 42 compared to 28 before the pandemic), and the building of a third premises, which will be concluded shortly.

When reflecting on his company’s evolution, the plant manager concludes, “I think that today, the right path for any SME is to invest in something that will, first of all, benefit the client, because then they will start to depend on you increasingly as suppliers and partners, not only as the manufacturers of specific products made by order. Another thing I consider just as important is that these SMEs find suppliers and partners (for technology, solutions, and services) that can support them through a process of competitive innovation. For us, this has been the case with PolyWorks Europa Italia. And I’ll finish with a short anecdote that will help you understand our company policy even better: Some time ago, a client expressed some doubts regarding the correct assembly of a piece saying that the scan, carried out by an external consulting agency, was showing a few out-of-tolerance measurements. We managed to put Alex in touch with the people in charge at this external consulting agency, and our trial inspector showed their technicians how to obtain the right alignment with respect to the main scan points. Moral of the story: In the end, when the measurements were repeated according to our instructions, the pieces were found to be fully compliant, and we were of course greatly satisfied. Bottom line: An entity with great expertise in pressed metal sheets taught the right measuring method to another entity that specializes in just that field…!”

OSIM has risen to success through the competitive monetization of metrology investments and nurtured a relationship with its clients in which product cost almost becomes secondary. The company now defines itself as “reference player when it comes to primary industrial entities for agricultural mechanization and industrial automation.”